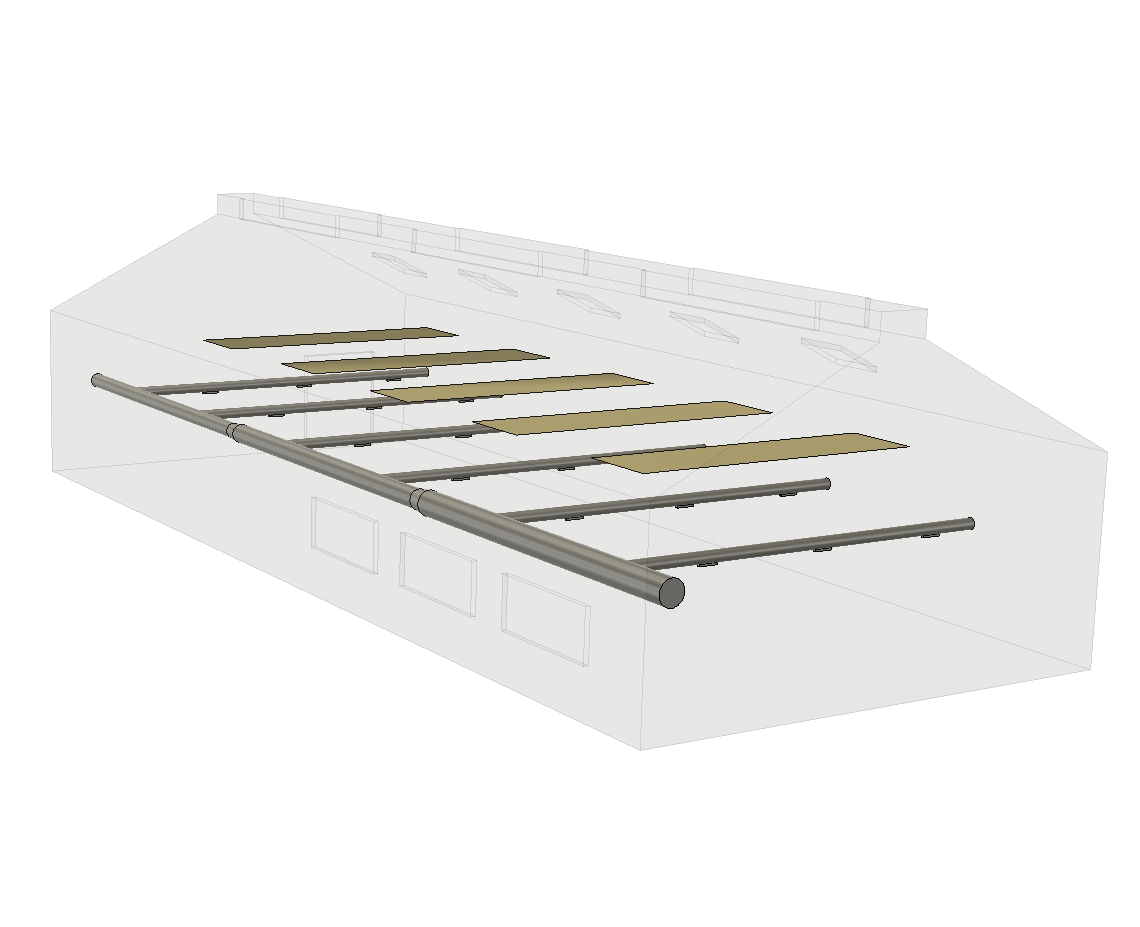

Project Description

Flow homogeneization in a SCR (Selective Catalytic Reduction)

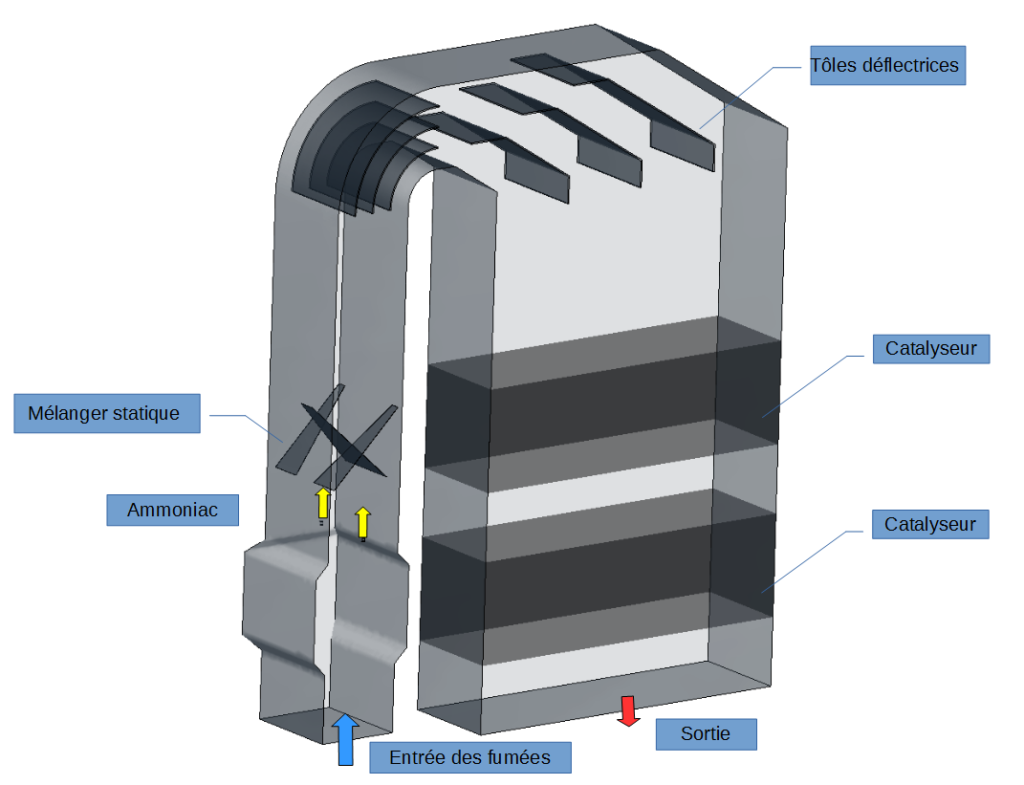

Industrial processes using boilers (cement plants, steel mills, incinerators, smelters …) are likely to release nitrogen oxides (NOx) in the atmosphere. To meet environmental standards, combustion smokes are treated in SCR SCR Selective Catalytic Reduction reactors. The principle is to react the NOx present in the fumes with ammonia which is sprayed in the flow.

The aim is to obtain a homogeneous mixture between the smokes and the pulverized ammonia when this mixture reaches the catalysts downstream. The catalysts and the passage section of the reactor are dimensioned so as to obtain an optimum smoke velocity to ensure a good reaction of the entire smoke flow. In addition to the homogeneity of the ammonia-smoke mixture, another objective is to ensure a homogeneous flow rate on the catalyst treatment section.

The size of these installations is sometimes very large (several tens of meters high), and each project is unique in its shapes and dimensions. It is therefore readily understood that it is difficult to “test” different solutions to achieve these objectives.

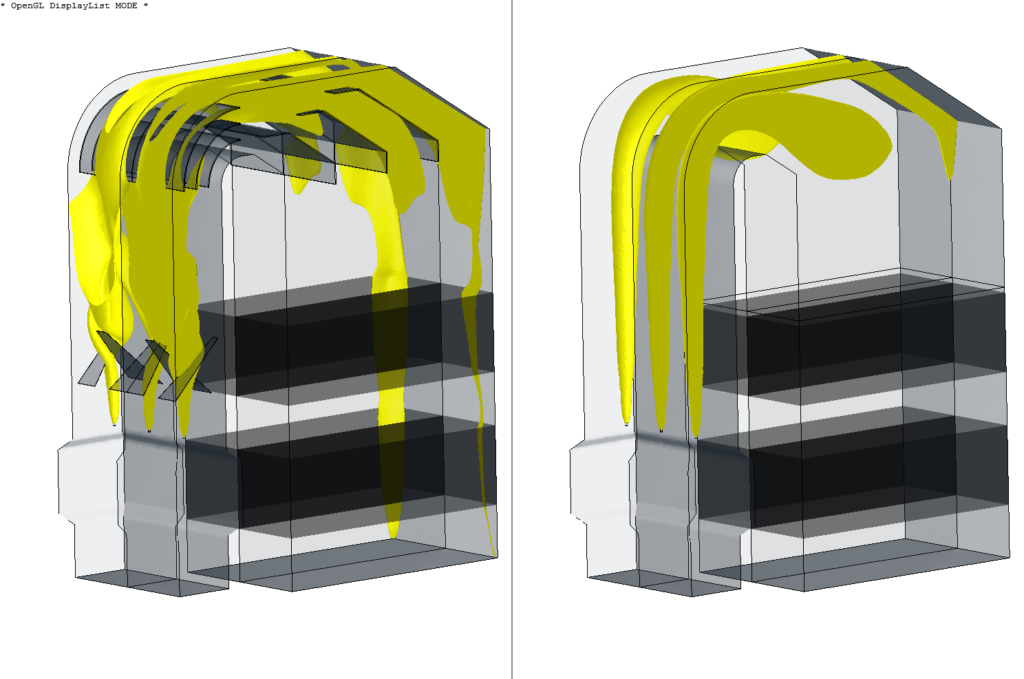

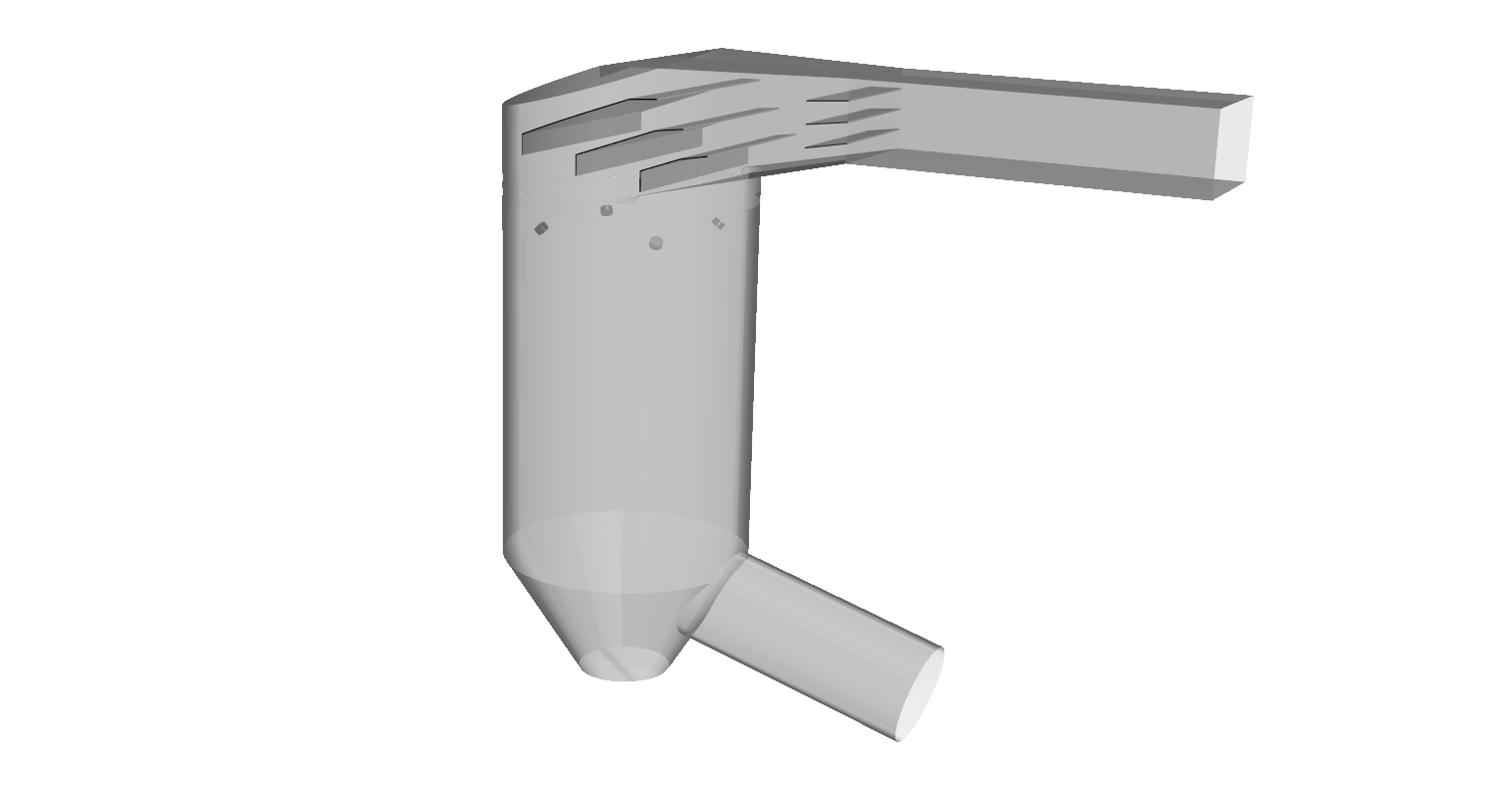

CFD Computational Fluid Dynamics (CFD) allows these numerical tests to be carried out in order to suitably dimension the mixers (mostly static) and the deflector plates which will lead to the best performances. The example shown here compares a SCR with some of the possible elements with an empty SCR of any homogenization solution.

Bondary conditions and physical modals

- A flow is imposed as input

- A pressure condition is imposed at the output

- An ammonia flow at the injection nozzles

- Turbulence is modeled

- The catalysts are modeled by media imposing equivalent pressure drops

- Only one half of the geometry is modeled

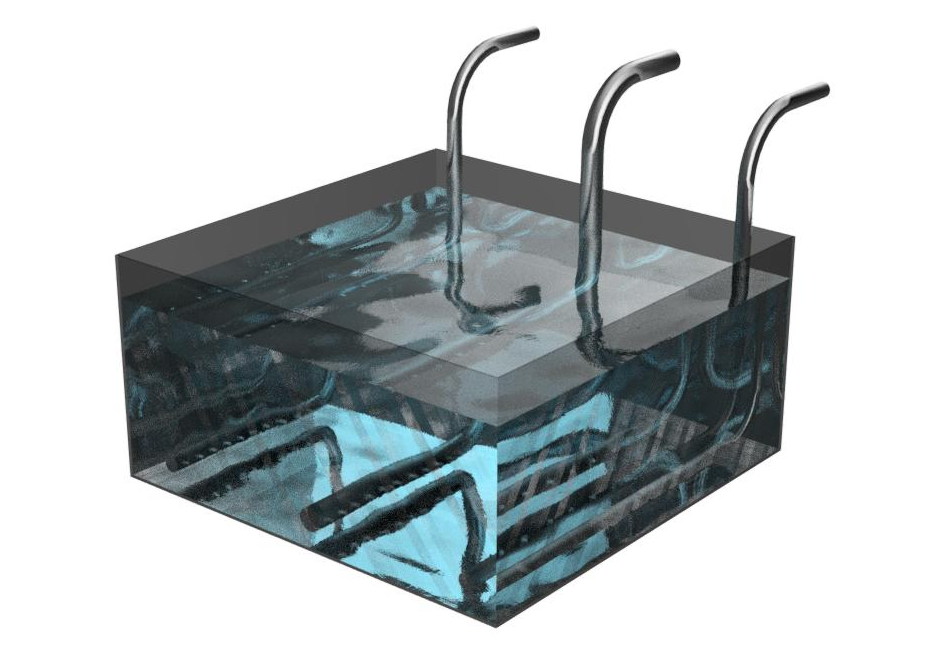

Simulation results

![Velocities in the symmetry plan [m/s]](https://numairo.fr/wp-content/uploads/2017/01/P08_scr_vit-sym-1024x679.png)

![Normales velocities in the control plan upstream the catalysts [m/s] - Positive velocities to the top](https://numairo.fr/wp-content/uploads/2017/01/P08_scr_vitz-control-1024x679.png)

![Pathlines colored by velocities [m/s]](https://numairo.fr/wp-content/uploads/2017/01/P08_scr_path-v-1024x679.png)

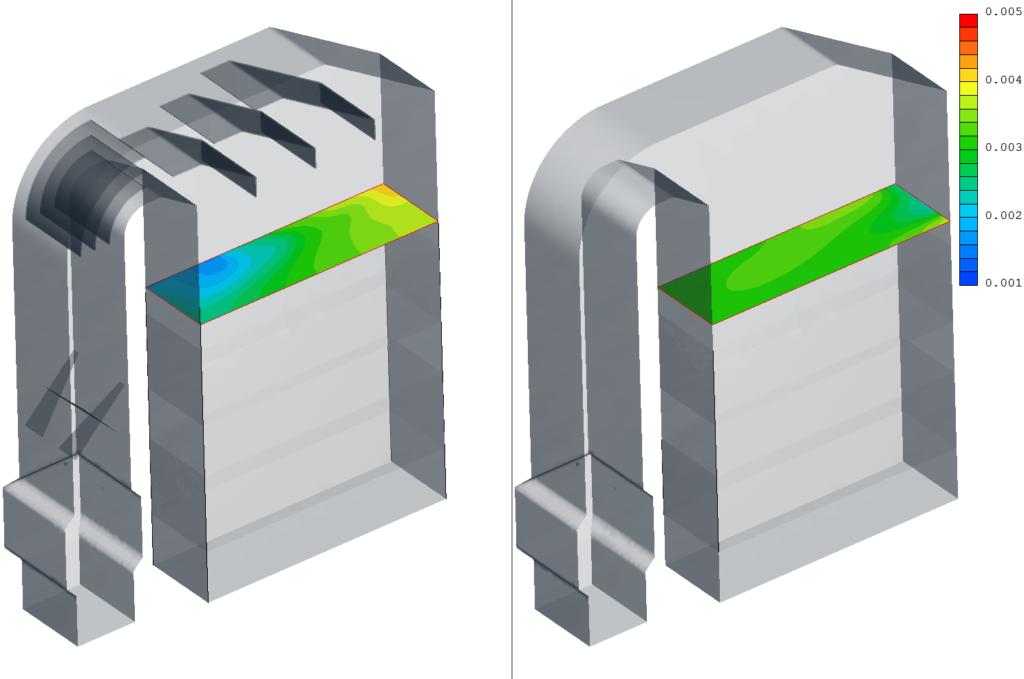

The SCR Selective catalytic reactor without these elements has a large recirculation loop caused by the sudden change in 180° direction of the fluid. The proposed solution of arranging the deflector plates in the installation makes it possible to straighten the flows efficiently. It is noted that the smokes reach the catalyst vertically, that is to say perpendicularly to the passage cross-section of the flue gases. The new configuration thus presents better aeraulic behavior performances. It is now advisable to check the quality of the Ammonia / Smoke mixture.

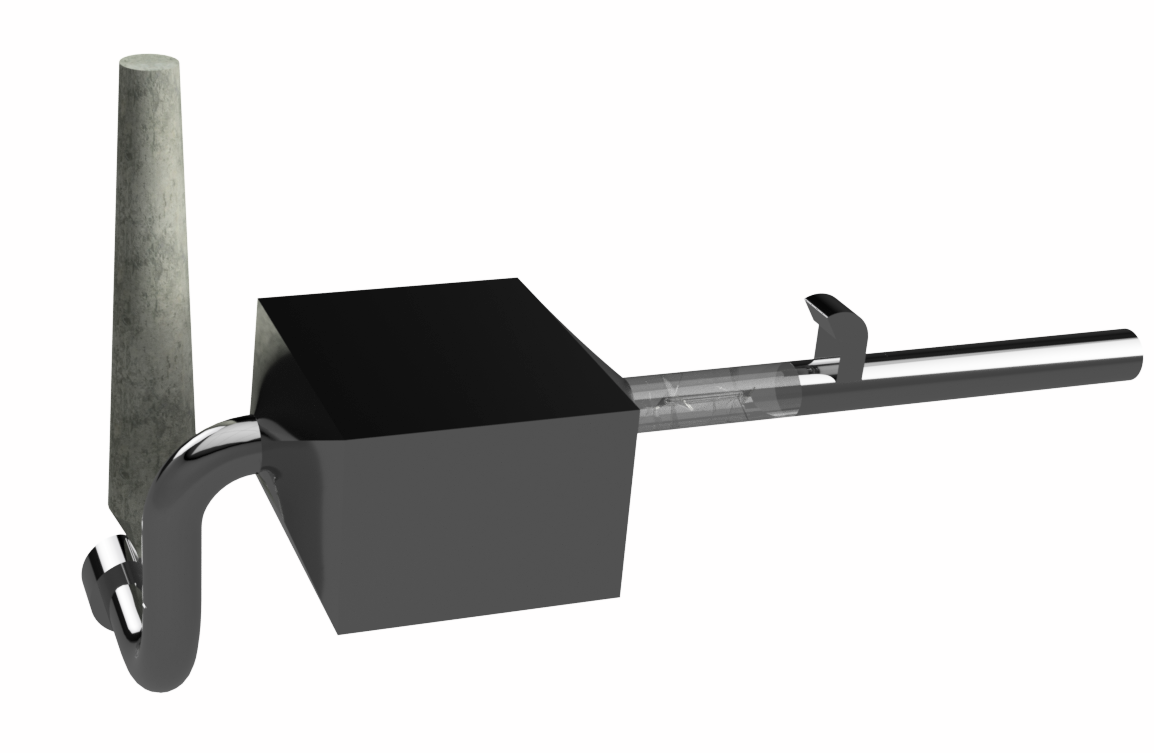

![Ammonia mass fraction in the symmetry plane [KgNH3/Kgsmokes]](https://numairo.fr/wp-content/uploads/2017/01/P08_scr_concentration-nh3-sym-cfd-1024x679.png)

L’analyse des concentrations dans l’appareil montre que l’utilisation des tôles déflectrices dégrade la qualité du mélange Ammoniac/Fumées. En effet, la grosse boucle de recirculation présente dans l’installation sans déflecteurs avait pour effet bénéfique d’améliorer le mélange. Sa suppression explique la disparité des concentrations observées sur la surface de contrôle.

Le mélangeur statique permet d’avancer le commencement du mélange dans la gaine montante de l’appareil. Cependant, celui-ci n’est pas suffisamment bien dimensionné pour répondre aux critères fixés par les nécessités du process et de la réglementation.

Il est enfin intéressant de relever l’impact des solutions d’homogénéisation sur la variation des pertes de charge (généralement augmentées) afin de s’assurer que le ventilateur sera toujours capable de délivrer le débit nominal.

Cet exemple est une illustration de l’utilité de la simulation numérique en mécanique des fluides CFD Computational Fluid Dynamics qui permets de tester rapidement une solution en évaluant ses effets attendus… et les effets secondaires éventuellement dommageables.